The Critical Difference Between Data Loggers and Real-Time Data Acquisition Systems

Small deviations in laboratory conditions can have huge consequences. A freezer door accidentally left open, a temporary CO₂ drop within a benchtop incubator, or an unforeseen power outage can compromise both experimental outcomes and the integrity of stored samples. In such situations, response time becomes paramount. For this reason, immediate alarming and continuous monitoring are fundamental requirements for laboratory safety. Equally important is the availability of complete historical records, allowing staff to analyse the sequence of events and identify both the root cause and its impact. This blog explores the tools laboratories most often rely on to meet these needs: Data Loggers and Real-time Data Acquisition Systems, such as XiltriX. While both approaches aim to protect science, their methods and limitations differ greatly. Understanding these differences is key to choosing the right system for environments where even the smallest event can make the biggest difference.

Mr. Han Weerdesteyn, CCO of XiltriX International commented: “Real safety comes not only from detecting problems in real time, but from understanding exactly why they happened and having the ability to provide a timely follow up to prevent damage.”

The limits of Traditional and Modern Loggers

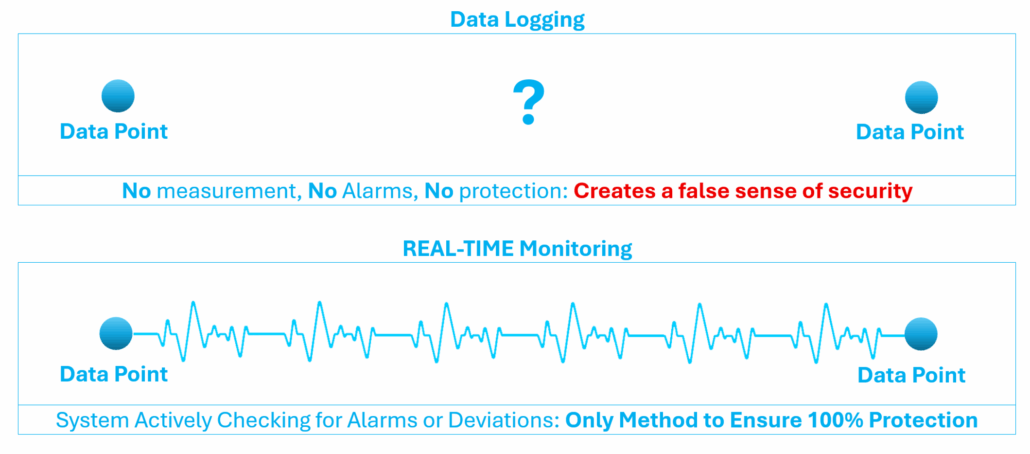

Data loggers have long been the default tool for laboratory monitoring. The earliest models were basic, battery-powered devices that stored environmental data at fixed intervals – sometimes hourly, sometimes every 30 minutes. They offered a useful record of past conditions but provided no opportunity to act in real time. If a failure occurred between measurements, it went unnoticed until much later, when a technician retrieved the data and the samples were already compromised.

Over time, technology advanced. Modern loggers became more sophisticated, capable of recording more frequent, up to every 15 or 30 minutes, and transmitting readings wirelessly to a base station or cloud platform. This made remote access possible and introduced basic alarms but also added new risks. Wireless signals can drop. Repeaters, often required to extend coverage, create additional single points of failure. If one fails, every logger connected through it may no longer have the ability to communicate. Even the central gateways have limitations. Installed inside the lab, they require secure internet access to access data externally. Maintaining that access and applying software or security updates is usually left to the customer. Few systems include failover protection, so when the internet goes down, so too does visibility and with it, the ability to raise alarms.

Han Weerdesteyn: “Modern loggers are smarter, but their core design still makes them reactive and therefore users are often too late. Only pro-active systems provide the control users are looking for.”

A Different Approach: Real-Time Data Acquisition Systems

This is where data acquisition systems take a different path. A system like XiltriX doesn’t rely on snapshots minutes apart but continuously collects data – often every few seconds – and sends it instantly to a secure platform. The moment a parameter drifts from its set range, an alarm is raised. There is no delay to the next scheduled measurement or transmission. From there, the benefits are evident. Instead of scattered devices and separate data sets, all sensors report into a single dashboard. Laboratories see a real-time overview of the entire facility: temperature, humidity, differential pressure, particle counters, CO₂, O₂, VOCs – all consolidated in one place. Action is taken based on live data, not historical data that appears to be live.

The Battery Problem

Power adds another layer of difficulty. To conserve battery life, most loggers are restricted in how often they measure and transmit, creating blind spots where short-lived but harmful events can go undetected. When logging transmission speeds would be raised, the need to change batteries is making these devices no longer fit for purpose. The batteries themselves are usually expensive and hard to source adding to e-waste and preventing labs for achieving sustainability goals. And while small sensors such as temperature may run on batteries, power hungry sensors, such as CO₂, O₂, VOC, particle counters and differential pressure monitors cannot. They require separate power supplies, undercutting the idea of a simple “wireless” setup.

By contrast, the architecture of a system like XiltriX is designed to avoid these weaknesses entirely. Its substations not only manage communication but also supply direct power to most connected sensors, including high-demand devices like CO₂ and VOC sensors. This eliminates the need for scattered power adapters and ensures that even the most energy-intensive sensors are seamlessly integrated. Installation is cleaner, monitoring is more reliable, and no critical parameter is left outside the network.

Mr. Han Weerdesteyn summarized: “A data logger can tell you what went wrong. XiltriX tells you what’s going to go wrong, while there’s still time to prevent damage to even the most precious samples.”

Installation

At first glance, data loggers seem attractive because they are quick to install: place a unit on a shelf, switch it on, and it begins recording. But when accuracy really matters, installation becomes far less straightforward. Proper placement of a temperature probe in a freezer or refrigerator is not as simple as dropping the sensor inside through a door gasket. A probe that sits too close to a cooling element can give falsely low readings, while one near the door might exaggerate fluctuations. CO₂ sensors in incubators pose an even greater challenge, as the location of the probe directly affects how representative the measurement will be and improper placement can even give rise to condensation or contamination issues.

Because loggers are designed to be “self-installed,” it is usually left to the laboratory staff to decide where and how to position them. Since this staff is usually not trained for this kind of job, it puts a heavy responsibility on the customer to understand airflow, equipment behaviour, and calibration requirements, something that is often overlooked. The result is that data may be incomplete or misleading, even if the logger itself is functioning correctly.

Han Weerdesteyn: In one laboratory, staff were confident that their -80°C freezer was stable because the logger showed no major deviations. The customer’s probe however, had been placed at the optimum location designated by the manufacturer. The freezer appeared to be functioning at peak efficiency. When the calibrated XiltriX sensor was placed at a more representative spot where actual samples were stored, it showed a 10°C higher temperature. This put the lab team in a tough spot, because it had to manually backtrack through years of historical alarm events to see if products were released, even though they had been stored at the wrong temperature.

Door sensors and Power failure

Alongside the temperature measurement, XiltriX hardware offers much more. By allowing the addition of door sensors as well as power failure detection and connection of the alarm outputs of the monitored devices, a lot ore information becomes available. Because the XiltriX hardware has multiple analogue and digital inputs, the costs of these additional sensors are negligible to the risk mitigation they provide.

When a user incorrectly closes a door of a -80°C freezer, the user will be notified of that fact within minutes, instead of being called out of bed in the middle of the night when the temperature has already risen up to -40°C. Having the ability to detect local power loss is also a big plus. When a user is notified of local power loss, the time to actual temperature deviations can be used to notify the technical staff and restore power, rather than doing damage control.

Continuous Support

Beyond the technology itself, the difference between loggers and XiltriX also lies in ongoing support. With data loggers, the responsibility for detecting issues often falls entirely on the customer. If a device stops recording or loses its connection, it may go unnoticed until data is retrieved, sometimes long after the fact creating huge traceability issues.

XiltriX takes a different approach. The monitoring system itself is under constant watch, backed by proactive 24/7 support. The technical team continuously checks system health, looking for early signs of signal loss, backup failures, or hardware malfunctions. If something is detected, they act immediately, often before the laboratory staff are even aware of a problem.

This means laboratories are not only alerted when conditions drift out of range but also reassured that the monitoring infrastructure itself is functioning correctly. And because expert help is available around the clock, staff know they have support even outside of working hours.

If you would like to know more about XiltriX, let me know.

Contact us