Erasmus MC Central Biobank relies on XiltriX for Risk Mitigation

Introduction

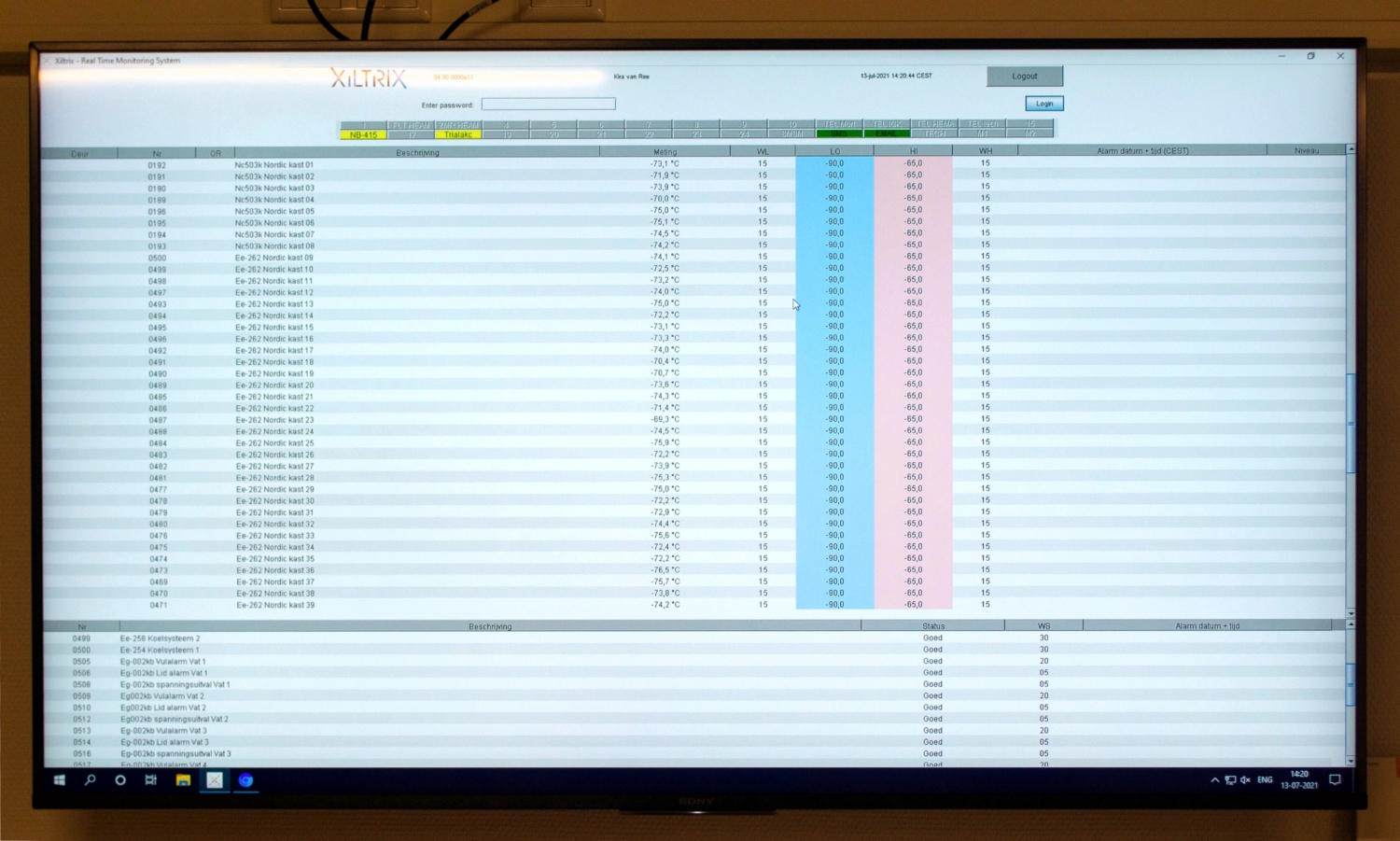

In February 2020 the construction of a central freezer facility started in the Erasmus Medical Center in Rotterdam. Moving away from individual ultralow freezers into a cuttingedge facility with (to start) 56 Nordic Freezers. These freezers, cooled by centrally provided cooling compressors, each provide room for up to 164.640 samples. XiltriX was tasked with providing the centralized monitoring and alarm solutions for this new Central Biobank Facility.

The Story of the Erasmus MC Central Biobank Facility

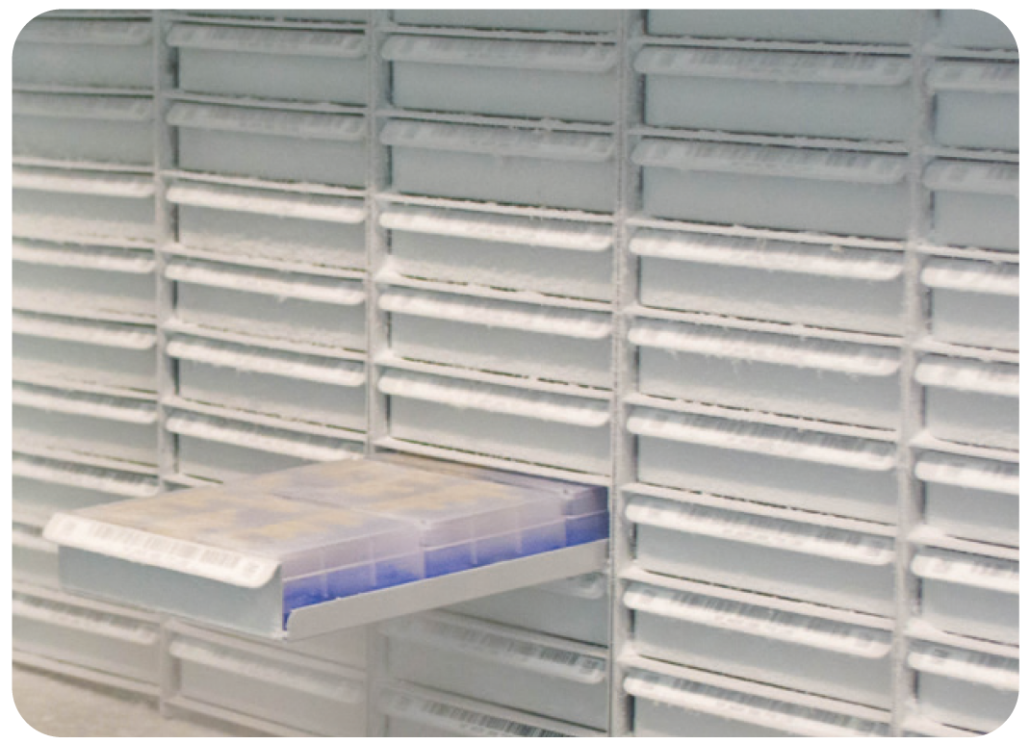

In recent years the need for securely storing samples at -196°C and -80°C conditions have exponentially risen. With hundreds of freezers scattered across multiple buildings and floors, management of samples, and the risk of losing them was of great concern to the Erasmus MC organization. As the leading teaching hospital in the Netherlands, Erasmus MC set out to build a facility that drastically lowered fire hazard, costs and energy consumption. The result is a fast-growing facility in which, not only a large number of samples are being securely stored, but is also taking over the whole management and sample tracking and tracing away from the individual departments and researchers. At the end of 2023 more than 5.8 million samples were stored in more than 77,000 storage boxes. Replacing conventional freezers with the novel Nordic freezers resulted in a total annual cost saving of almost €1.000.000. *Sources: https://www.erasmusmc.nl/en/research/facilities/centralbiobank#68ebd776-ab4e-40b5-8789-2394fdd68c17

Dr. Hilde Brouwers – da Silva has obtained her Master of Science degree in Biomedical Sciences from the Vrije Universiteit of Amsterdam (VU Amsterdam). After doing her PhD research at the Leiden University Medical Center (LUMC), she transferred to the Erasmus MC Biobank. She was promoted to Head of the Central Biobank in June 2022 and has been building out the facility ever since.

Dr. Hilde Brouwers – da Silva has obtained her Master of Science degree in Biomedical Sciences from the Vrije Universiteit of Amsterdam (VU Amsterdam). After doing her PhD research at the Leiden University Medical Center (LUMC), she transferred to the Erasmus MC Biobank. She was promoted to Head of the Central Biobank in June 2022 and has been building out the facility ever since.

Stages of the Implementation Process

Before building the Biobank facility a pilot installation was performed together with the supplier of the Nordic freezers Carnot. During the process several optimizations and upgrades to the design of the freezers were performed. This resulted in a freezer that was fit-for-purpose for the specific long-term storage Biobank task. Importantly Operational Qualification (OQ) and Performance Qualification (PQ) studies, using XiltriX independent temperature sensors, were performed making sure the Biobank knew exactly how long it would take for a freezer to heat up at fixed conditions and specific loads. Dr. Brouwers – da Silva commented: “With the temperature studies performed we have the peace of mind that even with big calamities we have up to 24 hours until the temperature inside our freezers reaches -60°C.”

The Nordic Freezer concept uses externally placed redundantly cooling compressors that provide the cooling fluids via super insulated pipes to a large number of highly insulated uprights cabinets fitted with freezers racks. The redundant systems allow the biobank to remain able to cool the freezers even during maintenance or failures. The benefits to users are numerous, for example the biobank has no need for any air conditioning in the room in which the freezers are placed, but still maintains a temperature of ±20°C. The complete cold chain is monitored by the manufacturer (on a technical level), but it also has XiltriX temperature and door sensors in every freezer.

XiltriX is also linked to the compressors to be able to gauge if the compressors are functional 24/7. The Nordic systems allow customers to reduce their power consumption up to 78%. Mr. Han Weerdesteyn CCO for XiltriX International said: “We extremely proud to be part of the Erasmus MC Biobank using these cutting-edge technologies. Safeguarding more than 5 million samples equates to a sample value of more than 500 million Euros. At XiltriX we are very aware there simply is no room for error.”

After commissioning the first part of the Central Biobank, the departments needed to start moving the samples into the new freezers. This process brought to light the lack of standardization between research departments at the time. Given the chance to do things right, an overarching Biobank Information Management System (BIMS) was put in place for tracking and tracing of all managed samples. This was important since the Central Biobank is in essence a managed service that Erasmus MC departments can trust their samples to for secure storage. Dr. Brouwers – da Silva recalled: “Working with multiple suppliers, it was very important to us they provided us with their knowledge and experience. We have been very happy working with the XiltriX team and their support. The system has been very reliable.

After commissioning the first part of the Central Biobank, the departments needed to start moving the samples into the new freezers. This process brought to light the lack of standardization between research departments at the time. Given the chance to do things right, an overarching Biobank Information Management System (BIMS) was put in place for tracking and tracing of all managed samples. This was important since the Central Biobank is in essence a managed service that Erasmus MC departments can trust their samples to for secure storage. Dr. Brouwers – da Silva recalled: “Working with multiple suppliers, it was very important to us they provided us with their knowledge and experience. We have been very happy working with the XiltriX team and their support. The system has been very reliable.

The Biobank is not only a number of freezers storing biological samples in a secure facility but is also dependent on a number of technical services. These services comprise of the large power demand, critical support from the freezer manufacturer in case of technical issues, and network and telephone services for XiltriX monitoring provided by the Erasmus MC facilities and IT organization. The XiltriX technical & Functional Management has been assigned to a team of 6 people in the Erasmus MC. This unique concept has resulted in a high level of quality and incidents being picked up more quickly preventing damage in the process. Leading the team Mr. Pascal van Elzakker commented: “I have been working with XiltriX for more than 15 years. Having worked in the laboratory I am intimately aware of what can go wrong. Working closely together with departments like the Central Biobank as part of the multi-tiered safetynet, we are crucial in preventing damage in case of big calamities.”

…………….

Download

A full version of this article can be downloaded by THIS DOWNLOAD LINK. Or click the link next to this article.

If you would like to know more about XiltriX, let me know.

Han Weerdesteyn

CCO